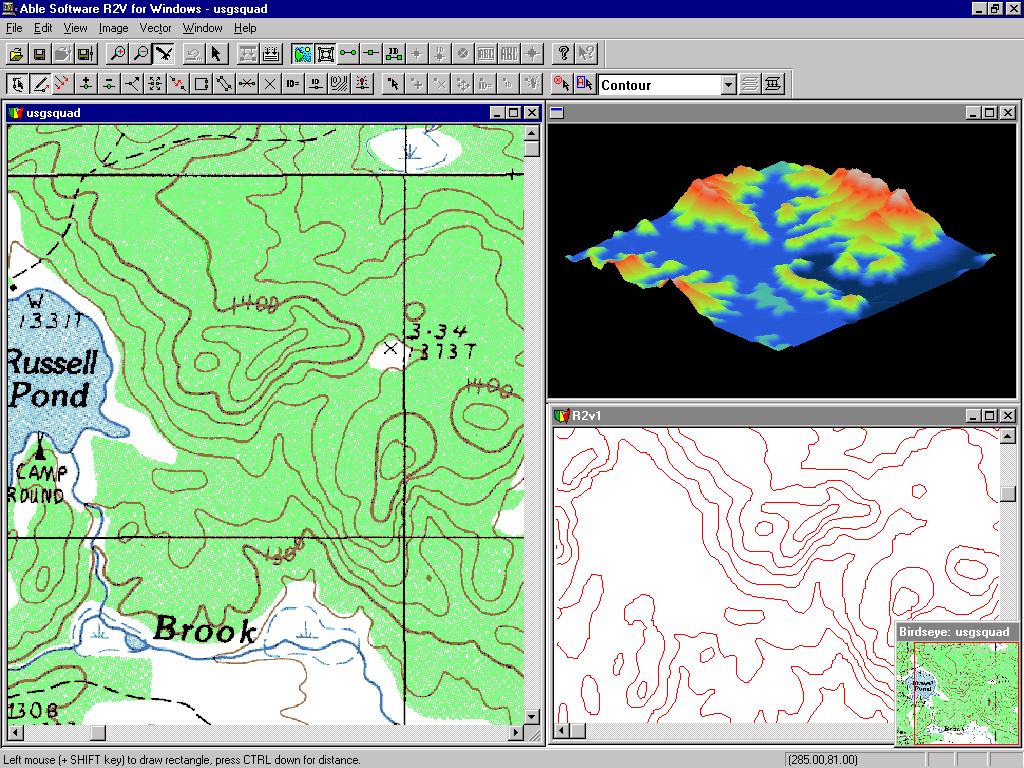

Contact us today to find out more about your options, and to get a quote on your job.I am working on a python script to slice a 3d model into 2d sections to be laser cut out of sheet stock and layered together.

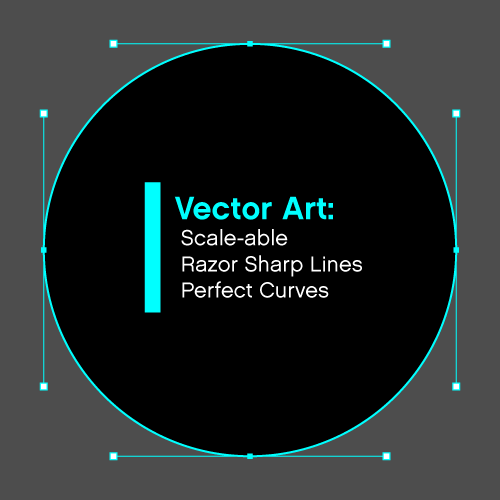

Not sure whether your file needs to be vector This process can be used to create extremely custom and unique parts that have both 2D cutouts as well as detailed 3D engraving. To do this, the file has to be specially designed to support both vector cutting and raster engraving. For example, a part may need an engraved design but also an irregular outline cut out. It’s possible that a part may use both vector cutting and raster engraving in combination. Here is an example of engraving on wood: Can You Use Vector Cutting and However, vector cutting is more commonly used on metals, including steel, titanium, brass, and aluminum. It should be noted that raster engraving is frequently used on soft materials, such as wood and leather. Raster image will engrave correctly into the desired end product. This process usually takes additional preparation to ensure that the Raster engraving can be used to cut preciseĭetails into a flat plane, but because of this, it also takes longer than vectorĬutting. The way through the material but rather needs cuts at different depths, then If your end product doesn’t need to be cut all To cut a 3D image into a flat sheet of material. Raster engraving should be used when you want Vector cutting is mainly used on metals butĬan also be used for wood, cork, paper, and plastic. Long as your image can be entirely expressed in terms of an outline, vector Production of 2D parts, and it can be used with a wide variety of materials. Vector cutting is the fastest and easiest way to achieve this. Product – if the entire product is composed of lines that need to be cut, then Need to cut out a 2D image from a flat sheet of material. Vector cutting should be used any time you Raster engraving will produce an engraved surface in a complete plane. Vector cutting will produce a cut outline whereas Inherently better than the other, as they are both used for dramaticallyĭifferent applications. Neither vector cutting nor raster engraving is Raster engraving is often used in wood and metal plaques and Raster engravingĭoesn’t necessarily cut all the way through the metal piece instead, itĬreates a relief. Raster image is composed of pixels, which have varying color. Rather than being composed of lines and points, a With raster engraving, a laser head is used toĬut down into a material to a certain depth, with this depth controlled by theĬolors of a raster image.

Vector cuts are frequently used for metal signs, decorative metal features, machine parts, jewelry, and more. After a vector cut, you will have a 2D piece that has been cut out, using the outline. Vector images are images that are composed of lines and points they can be easily scaled up and down, as the image itself is expressed in mathematical algorithms. With vector cutting, a laser cuts along a line that is defined by a vector image. Process and the types of images that are used. Our laser cutting process uses “vector cutting” for fast, precise 2D part production.īut what is vector cutting and how does itĬompare to similar methods such as raster engraving?

0 kommentar(er)

0 kommentar(er)